Polycrylic vs. Polyurethane Comparison Guide

Determine Which Is Best for Wood Projects at Home

The Spruce / Dennis Madamba

Reviewed by Deane Biermeier

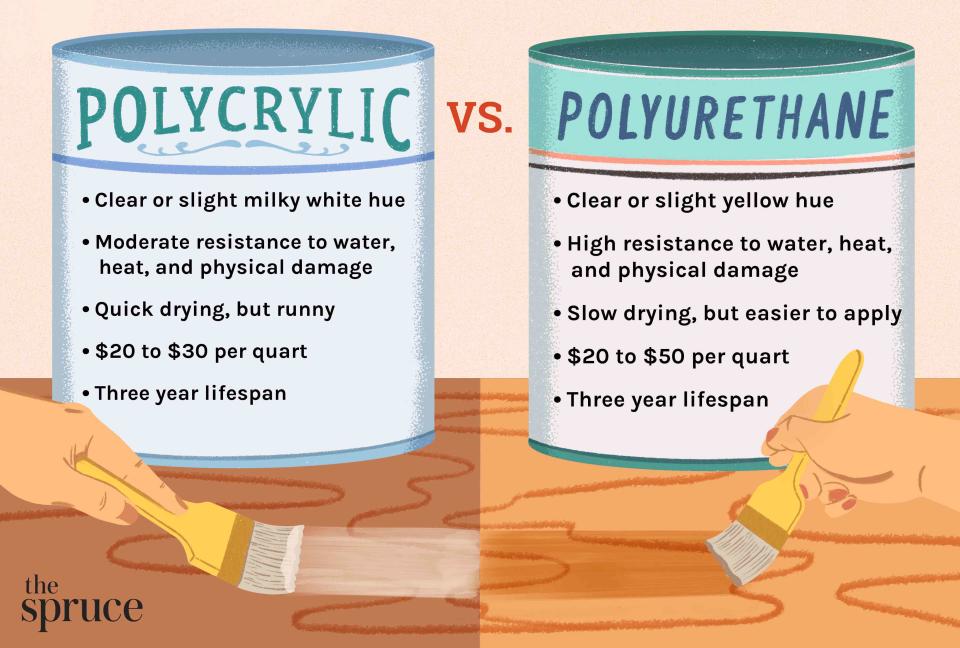

Polycrylic and polyurethane are two common wood sealers that experienced woodworkers often use to finish their projects. However, they can confuse new DIYers since they have a similar name and purpose.

Polycrylic is a light-duty sealant that dries quickly with a clear or slightly milky hue. It's low in flammability and volatile organic compounds (VOCs). It isn't as durable as polyurethane and should be considered for furniture like cabinets, trim, and decor.

Polyurethane is better for high-traffic areas like wood floors, though it does take longer to dry. Oil-based polyurethane is a flammable product with a high level of VOCs. Water-based polyurethane still has a higher level of VOCs than polycrylic.

Use this guide to understand the differences and similarities of polycrylic vs. polyurethane and learn more about the benefits and drawbacks of each for your next woodworking project.

Polycrylic vs. Polyurethane: Major Differences

While the main purpose of polycrylic and polyurethane is essentially the same, some significant differences set these products apart.

Polycrylic is a water-based product that tends to dry quickly with a clear or slight milky white hue and will last about three years before needing to be retouched.

Polyurethane can be either water-based or oil-based. It doesn't dry as quickly as polycrylic, but polyurethane is easier to apply and has a higher resistance to water, heat, and physical damage. Water-based polyurethane, like polycrylic, can be cleaned with soap and warm water, but oil-based polyurethane needs to be cleaned with mineral spirits or paint thinner.

Typically, polycrylic costs about $20 to $30 per quart, and it's relatively safe to use because it is non-flammable and has a low level of VOCs. Polyurethane costs more, at about $20 to $50 per quart. It dries with a clear or slight yellow hue and generally lasts three years before needing to be refinished.

| Polycrylic | Polyurethane |

Appearance | Clear or slight milky white hue | Clear or slight yellow hue |

Water and Heat Resistance | Moderate resistance | High resistance |

Care and Cleaning | Clean with warm water and soap | Clean water-based with warm water and soap. Clean oil-based with mineral spirits |

Durability and Maintenance | Moderate resistance to physical damage | High resistance to physical damage |

Application | Quick drying, but runny and difficult to apply to vertical surfaces | Slow drying, but easier to apply |

Cost | $20 to $30 per quart | $20 to $50 per quart |

Lifespan | About three years | About three years |

Environmental Impact | Low personal risk and environmental impact | High personal risk and environmental impact |

Appearance

Polycrylic

When you are looking for a polycrylic product to seal your woodworking project, you can find satin, gloss, high gloss, and matte finishes. Select the best option based on the look of your finished project. Remember that polycrylic tends to appear milky white during application, though it is typically clear when it dries. If you apply the polycrylic in thick coats, it may retain a slight milky white hue.

Polyurethane

Polyurethane users can find both water-based and oil-based versions in satin, gloss, and high gloss finishes. The appearance of the polyurethane sealant depends on whether it is water-based or oil-based. A water-based polyurethane product will generally dry completely clear, but an oil-based product typically retains a slight yellow hue.

Best for Appearance: Tie

There isn't a significant difference between these products. Both can dry clear or have slight tinges of residual color, though polycrylic has a slight edge over polyurethane due to a higher number of finish options.

The Spruce / Sanja Kostic

Water and Heat Resistance

Polycrylic

A sealant protects the object it is applied to from moisture, heat, and physical damage. Polycrylic cleans furniture, keeping wooden furniture safe from spills and mild burns, though it is not suitable for outdoor application. This is because polycrylic only has a mild to moderate resistance against water and heat. Rain, snow, sleet, hail, and long periods spent in direct sunlight would inevitably damage the wood.

Polyurethane

Use polyurethane to protect your woodworking projects and delicate furniture for a more water and heat-resistant option. Oil-based polyurethane has a high resistance level against moisture, UV radiation, and heat, ensuring that the wood remains protected. Water-based polyurethane does not have the same resistance as oil-based polyurethane.

However, only polyurethane (of either type), explicitly labeled as a sealant for outdoor furniture, should be used for exterior projects or on items that will spend much of their time outdoors.

Best for Water and Heat Resistance: Polyurethane

A primary reason to use a sealant to finish your woodworking project is to keep the wood safe. In this regard, oil-based polyurethane is the best choice. It has a high level of resistance against water, heat, and UV radiation, making it an excellent option for sealing high-traffic floors or furniture with heavy use.

Care and Cleaning

Polycrylic

After applying polycrylic to wooden furniture, you may have a mess to clean up. Fortunately, polycrylic can be cleaned with only soap, warm water, and little physical effort. Once the polycrylic layer on the furniture or woodworking project is dry and fully cured, it can be washed with a damp cloth without worrying about water damage.

Polyurethane

When your woodworking project has been finished with a water-based polyurethane coat, you can clean up any drips or spills with warm water and soap. However, oil-based polyurethane must be cleaned with mineral spirits or paint thinner. After allowing the polyurethane to dry, you can keep the woodworking project clean by wiping it down or scrubbing it with a damp cloth to remove dust, dirt, or grime.

Best for Care and Cleaning: Polycrylic

All you need to clean up after using polycrylic is soap and warm water. You can also clean water-based polyurethane with soap and warm water, but the drawback to using oil-based polyurethane is that you need to rely on mineral spirits or even paint thinner to clean up any drips or spills.

Durability and Maintenance

Polycrylic

Protecting the wood against water and heat is only part of a sealant's job. This finish should protect the object from physical damage, like scratches or dents. Polycrylic is a durable choice that can provide moderate protection to wooden furniture or floors. It acts as a thin barrier, preventing direct damage to the wood, though polycrylic does not hold up as well as polyurethane.

Polyurethane

If you plan on applying a protective finish to a high-traffic area of a wooden floor or a commonly used piece of furniture, like a chair, then polyurethane is the best option. It is a high-durability product that can protect the wood from scratches, dents, chips, nicks, and the usual wear-and-tear to which high-traffic locations and objects are often subjected.

Specifically, oil-based polyurethane is the most durable choice to keep your wooden furniture, floors, or woodworking projects safe.

Best for Durability and Maintenance: Polyurethane

Oil-based polyurethane is made to hold up against physical abrasion, scratches, dents, chips, nicks, and more. This durable finish protects the underlying wood to keep the object in good condition, even in high-traffic areas.

Water-based polyurethane is not as durable as oil-based products, so investing in an oil-based polyurethane is recommended to increase the durability of your floors, furniture, or any other high-use surfaces.

Application

Polycrylic

One of the drawbacks of polycrylic is that it has a loose, runny consistency that can be difficult to apply to vertical surfaces. It dries quickly, making it a great choice for small woodworking projects. However, due to the speed at which the product dries, it's hard to get it to dry smoothly, even coats on larger woodworking projects. Polycrylic should be applied with a brush or sprayer in three thin coats.

Polyurethane

Make sure you are working in a well-ventilated space and that you are wearing a respirator that is designed to filter out VOCs. Polyurethane is generally easier to apply than polycrylic because it has a thicker consistency. Use a brush or sprayer to apply polyurethane in about three coats. It's recommended to lightly sand each coat after it has had time to dry to give the next coat better surface adhesion.

Polyurethane is a better option for finishing large woodworking projects. Just be careful not to shake, swish, or otherwise churn the polyurethane, as this can create bubbles that will stick to the surface of the wood and need to be sanded before a second or third coat can be applied.

Best for Installation: Tie

Generally, polyurethane is easier to apply to large projects and vertical surfaces because the product is thicker, so it doesn't run during application. However, polycrylic is a non-flammable, low-VOC option that is easier indoors than polyurethane. It also dries noticeably faster, making it a good choice for small woodworking projects.

Cost

Polycrylic

If finish cost is a deciding factor, then polycrylic is the way to go. On average, it costs about $20 to $30 per quart. However, it's necessary to note that this is about the same price as a water-based polyurethane product.

Polyurethane

Regarding the price, polycrylic and water-based polyurethane are about the same. Oil-based polyurethane costs slightly higher, ranging from about $20 to upwards of $50 per quart.

Best for Cost: Polycrylic

Polycrylic has a slight advantage over polyurethane due to the higher cost of oil-based polyurethane products. However, you can get a water-based polyurethane product for about the same price as a polycrylic product.

Lifespan

Polycrylic

The lifespan of a sealant refers to the length of time between the initial application and when it needs to be retouched or refinished. On average, polycrylic will last about three years before it should be refinished to ensure the continued safety of the floor, furniture, or other wooden objects.

Polyurethane

Polyurethane has essentially the same lifespan as polycrylic. You should plan to refinish or retouch the polyurethane sealant on a woodworking project, piece of furniture, or wooden floor about once every three years.

Best for Lifespan: Tie

In this category, both polycrylic and polyurethane are equal. After applying either of these finishes, it's a good idea to reapply or retouch the finish about once every three years.

Environmental Impact

Polycrylic

While you work, the environment and anyone nearby will thank you for using polycrylic over polyurethane. Polycrylic is a non-flammable sealant that doesn't have a strong chemical odor. It also has lower VOCs, though working in a well-ventilated space with an appropriate mask is still recommended.

Polyurethane

Polyurethane is not an environmentally friendly option. It's a combustible substance that gives off powerful chemical odors and is high in volatile organic chemicals (VOCs). Water-based polyurethane isn't as bad as oil-based polyurethane, but the VOC count is still relatively high. Always make sure to work in a well-ventilated area when you are applying polyurethane.

Best for Environmental Impact: Polycrylic

Polycrylic is a non-flammable substance, has lower VOCs, and does not produce the same chemical odor as polyurethane. Water-based polyurethane is better than oil-based polyurethane but isn't as environmentally friendly as polycrylic.

The Verdict

After weighing the benefits and drawbacks of polycrylic vs. polyurethane, it becomes clear where and when to use each product. Polycrylic is a great finish option for small woodworking projects that will remain indoors and receive relatively limited interaction, like cabinets, trim, or seldom-used wooden furniture.

Water-based polyurethane should primarily be used on indoor furniture, wood floors, and other wooden objects that experience moderate use. It is more durable than polycrylic, allowing it to hold up better than polyacrylic.

Oil-based polyurethane is the best option for finishing high-traffic wood flooring or commonly used indoor furniture. Use only polyurethane products labeled for outdoor use on exterior projects, whether water- or oil-based.

Top Brands

Polycrylic

Minwax (only brand that makes polycrylic)

Polyurethane

Varathane

Rust-Oleum

BEHR

Frequently Asked Questions

Does polycrylic make the surface waterproof?

Polycrylic makes a surface water- and stain-resistant but not waterproof. Polyurethane has higher resistance to water than polycrylic.

Does polycrylic make wood shiny?

Polycrylic makes wood shine after application. Different polycrylic products have varying sheen levels, from flat to glossy.

Will polycrylic turn yellow?

Polycrylic doesn't turn yellow, while polyurethane might. However, polycrylic can sometimes get a milky or cloudy cast over time, making polyurethane a better choice for darker woods and polycrylic better for lighter woods.

Read the original article on The Spruce.