Colorado Researchers Make Dissolvable Duds from Gelatin

Imagine wearing a T-shirt a few times then getting sick of it. Instead of tossing the tee, it’s dissolved to be recycled into a new shirt.

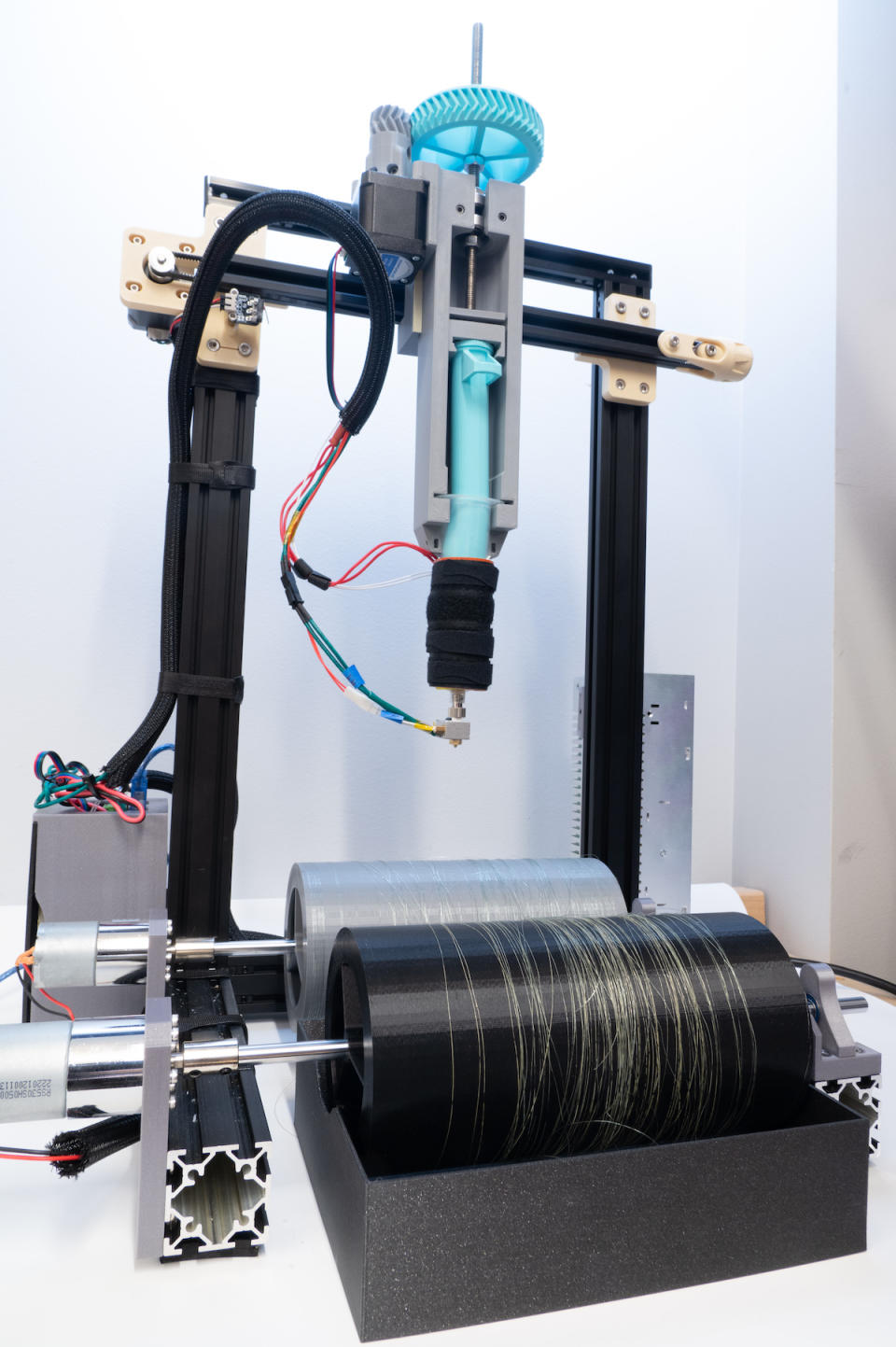

Researchers at the Atlas Institute at the University of Colorado Boulder are closing in on the possibility of doing just that. In a new study, a team of engineers and designers from the interdisciplinary institute for creative technologies developed a DIY machine that spins gelatin-based fibers into yarns to be knitted or woven into garments. The group’s “biofibers” feel like flax fiber, according to the university, and dissolve in hot water in minutes to an hour.

More from Sourcing Journal

“When you don’t want these textiles anymore, you can dissolve them and recycle the gelatin, said Michael Rivera, a co-author of the research and assistant professor at the Atlas Institute and Department of Computer Science.

Ideally, the process would be dissolving an item of clothing, recycling the gelatin to make more fibers and, ultimately, creating new clothing—all possible with the DIY machine that’s small enough to fit on a desk and costs $560 to build. The team, led by Eldy Lázaro Vásquez, a doctoral student at the Atlas Institute, hopes to tackle the mounting issue of textile waste by envisioning a different, unexplored path for fashion. The team also hopes that the device will help designers globally experiment with making their own biofibers.

“You could customize fibers with the strength and elasticity you want, the color you want,” Lázaro Vásquez said. “With this kind of prototyping machine, anyone can make fibers. You don’t need the big machines that are only in university chemistry departments.”

To imagine a new way of making clothing, the researchers began with gelatin: a springy protein found in the bones of many animals that’s thrown away in mass quantities when it doesn’t meet the requirements of the food or cosmetics industries. Lázaro Vásquez actually bought her own gelatin (which comes as a powder) from a local butcher shop to turn “waste into wearable treasure.”

Using a plastic syringe, the group’s machine heats up and squeezes out droplets of a liquid gelatin mixture. Two sets of rollers in the machine then “tug” on the gelatin, stretching it into long, skinny fibers akin to those of a spider spinning its web. During the process, the fibers pass through liquid baths. This is when the team can introduce biobased dyes (or other additives) to the material. Adding genipin—a from fruit extract—strengthens the fiber, for example.

As a proof-of-concept, the team made small textile sensors out of gelatin fibers, cotton and conductive yarns. The researchers then submerged these patches in warm water, which caused the gelatin to dissolve and release the yarns for easy recycling or reuse.

Of course, designers should tweak the chemistry of the fibers to fit their individual needs; a jacket shouldn’t dissolve in the rain, for example. Designers are also encouraged to tinker with spinning similar fibers from other natural ingredients, something like chitinfrom crab shells or agar-agar from algae. And the team isn’t just saying that—the source files for the desktop biofibers spinning machine are available for download on the code-hosting platform GitHub.

“We’re trying to think about the whole lifecycle of our textiles,” Lázaro Vásquez said. “That begins with where the material is coming from. Can we get it from something that normally goes to waste?”

The research, “Desktop Biofibers Spinning: An Open-Source Machine for Exploring Biobased Fibers and Their Application Towards Sustainable Smart Textile Design,” was authored by Lázaro Vásquez and Rivera. Co-authors include Mirela Alistar and Laura Devendorf, both assistant professors at Atlas.

The research team, led by Lázaro Vásquez, presented these findings at the CHI Conference on Human Factors in Computing Systems in Honolulu in May.